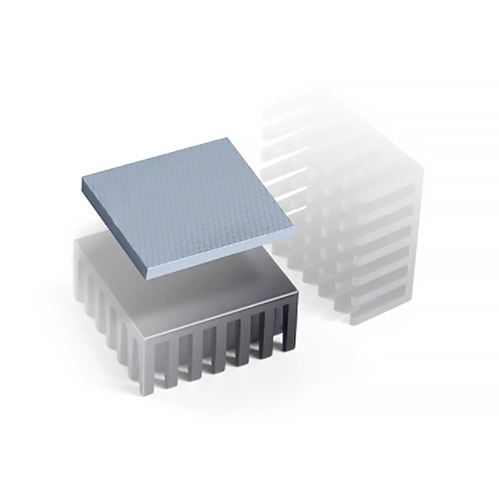

- Thermal-Pad

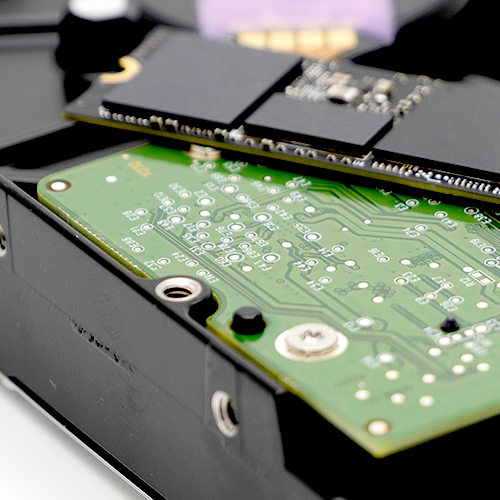

- Gap-Filler

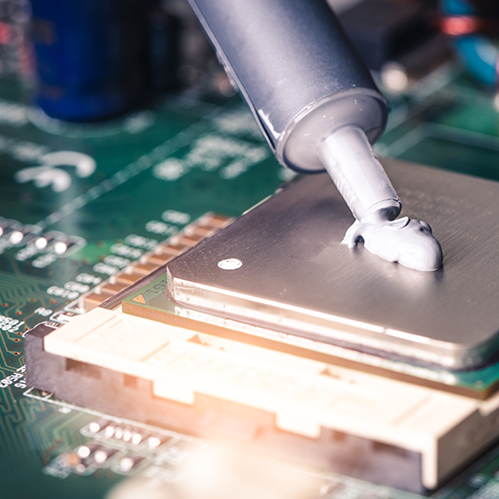

- Thermal-Grease

|

高导热系数

高导热系数

|

|

可灵活地调整物性

可灵活地调整物性

|

卓越的附着力

卓越的附着力

|

|

易于使用

易于使用

|

Scroll >>

| ITEM |

Unit |

KBE-TPDS10 |

KBE-TPDS30 |

KBE-TPDS60 |

Note |

| Thermal conductivity |

(W/mk) |

1.0 |

3.0 |

6.0 |

ASTM D5470 |

| Color |

- |

White, gray |

White, gray |

White, gray |

- |

| Density |

(g/cm3) |

1.6 |

3.03 |

3.4 |

ASTM D792 |

| Hardness |

(shore ○○) |

20~30 |

40~50 |

60~70 |

ASTM D2240 |

| Volume resistance |

(Ω·cm) |

1x1014 |

1x1014 |

1x1014 |

ASTM D257 |

| breakdown Voltage |

kV |

>15 |

>15 |

>15 |

ASTM D149 |

| Thermal stability |

-40~150℃ |

No change |

No change |

No change |

- |

| Thickness |

mm |

1, 2, 4 |

1, 2, 4 |

1, 2, 4 |

- |

| Flame rating |

UL94 |

V-0 |

V-0 |

V-0 |

- |

|

极低粘度,无需其他设备也容易使用

极低粘度,无需其他设备也容易使用

|

|

附着力、可加工性和工作时间卓越

附着力、可加工性和工作时间卓越

|

容易渗透到微细结构

容易渗透到微细结构

|

Scroll >>

| ITEM |

Unit |

KT-L1000 |

KT-L3000 |

Note |

| Thermal conductivity |

(W/mk) |

1 |

3 |

ASTM D5470 |

| Viscosity(mixed) |

Pa.s |

10~20 |

200~300 |

Brookfield |

| Color |

- |

White, gray |

White, gray |

- |

| Density |

(g/cm3) |

1.8 |

3 |

ASTM D792 |

| Hardness |

(shore ○○) |

20~30 |

30~40 |

ASTM D2240 |

| Volume resistance |

(Ω·cm) |

1x1014 |

1x1014 |

ASTM D257 |

| breakdown Voltage |

kV |

>15 |

>15 |

ASTM D149 |

| Thermal stability |

-40~150℃ |

No change |

No change |

- |

| Flame rating |

UL94 |

V-0 |

V-0 |

- |

| Pot-life |

25oC/min |

60 |

60 |

- |

|

根据,涂抹方式,导热系数会有所不同

根据,涂抹方式,导热系数会有所不同

|

|

卓越的使用寿命

卓越的使用寿命

|

高导热系数

高导热系数

|

Scroll >>

| ITEM |

Unit |

KT-L1000 |

Note |

| Thermal conductivity |

(W/mk) |

10 |

ASTM D5470 |

| Viscosity |

poise |

900 |

Brookfield |

| Color |

- |

gray |

- |

| Density |

(g/cm3) |

2.5 |

ASTM D792 |

| Volume resistance |

(Ω·cm) |

1x1014 |

ASTM D257 |

| Thermal stability |

-20~120℃ |

No change |

- |

由于耐热性、绝缘性和耐化学性等化学特性,以及柔韧性和弹性附着力的物理特性,在安装中具有高导热性

由于耐热性、绝缘性和耐化学性等化学特性,以及柔韧性和弹性附着力的物理特性,在安装中具有高导热性

可定制产品,满足客户需求

可定制产品,满足客户需求

基于适用于点胶和灌封的流动性,容易渗透至复杂狭窄的形态,可在常温和高温加固

基于适用于点胶和灌封的流动性,容易渗透至复杂狭窄的形态,可在常温和高温加固

可定制产品,满足客户需求

可定制产品,满足客户需求

发出高热的 CPU、AP 芯片等,作为电子部件和盖板的金属,

发出高热的 CPU、AP 芯片等,作为电子部件和盖板的金属, 去除界面之间气孔,顺畅导热

去除界面之间气孔,顺畅导热

可定制产品,满足客户需求

可定制产品,满足客户需求